When considering an investment in an envelope press—whether your current device is old or broken or you’re retiring your offset press—you will likely look at both inkjet and toner. They differ greatly, so here are a few questions to ask yourself.

Sheen or Flat?

Perhaps you don't care and are ready to move on to talking dollars and pennies, but for those who have an eye of a pressman, you’ll want to consider what qualities are important to you in the output of a job. Toner will produce a sheen look while inkjet is flat. Inkjet can bleed off the edge while you’re limited in design with toner. Toner devices can crease or emboss envelopes while inkjet uses no pressure.

operating costs?

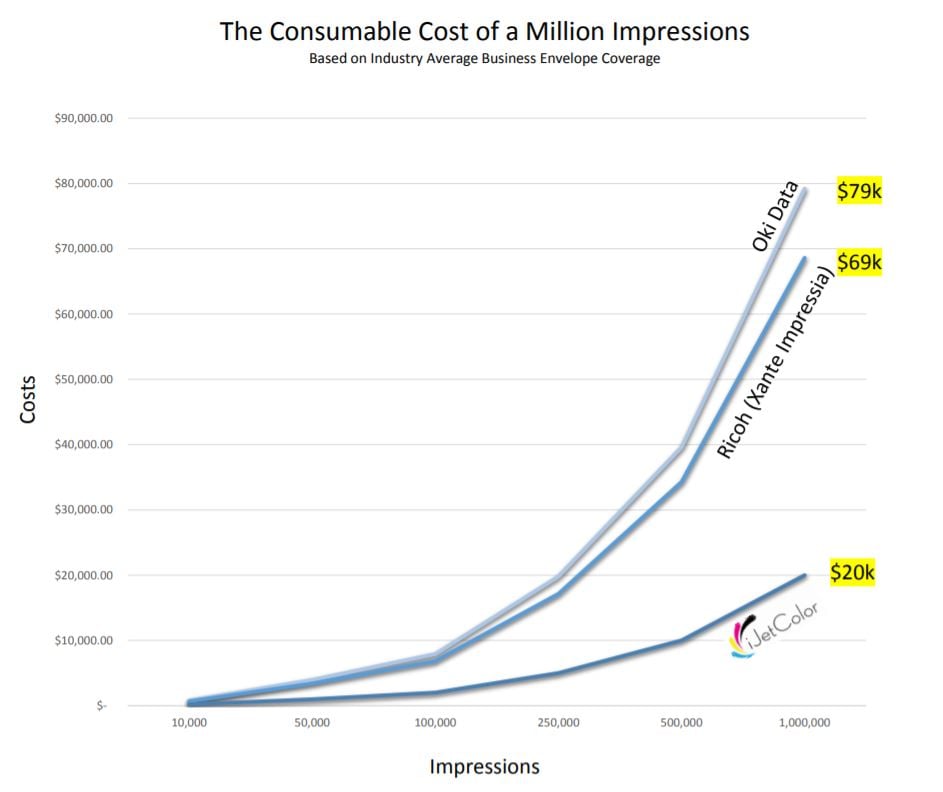

This is a big one for business owners. It’s easy to first look at the sticker-price of equipment to determine affordability, but we know operating costs matter when it comes to printing. Inkjet is ½ to 1/3 the cost of toner to operate which means inkjet provides the greater profit.

service options?

The complex feed system and part design of toner-based systems is inclined to requiring more service, and service is often completed only when a technician is available to come onsite. Inkjet benchtop systems have a simple feed design requiring less service. In such cases where service is required, 24/7 phone support options are available to provide fast service to keep you up and running.

Dedicated envelope devices are important to keep up with demand, but choosing the right type for your business is critical to keeping up with demand and pleasing customers (and your bottom line) while doing it.